Rotary Transfer Gear Pumps

5000 INR/Piece

Product Details:

- Usage Agriculture

- Material Cast Iron

- Structure Diaphragm Pump

- Fuel Type Diesel

- Color Blue

- Click to View more

X

Rotary Transfer Gear Pumps Price And Quantity

- 1 Unit

- 5000 INR/Piece

Rotary Transfer Gear Pumps Product Specifications

- Diaphragm Pump

- Agriculture

- Cast Iron

- Blue

- Diesel

Rotary Transfer Gear Pumps Trade Information

- 50 Unit Per Month

- 3-4 Week

- Middle East

- All India

Product Description

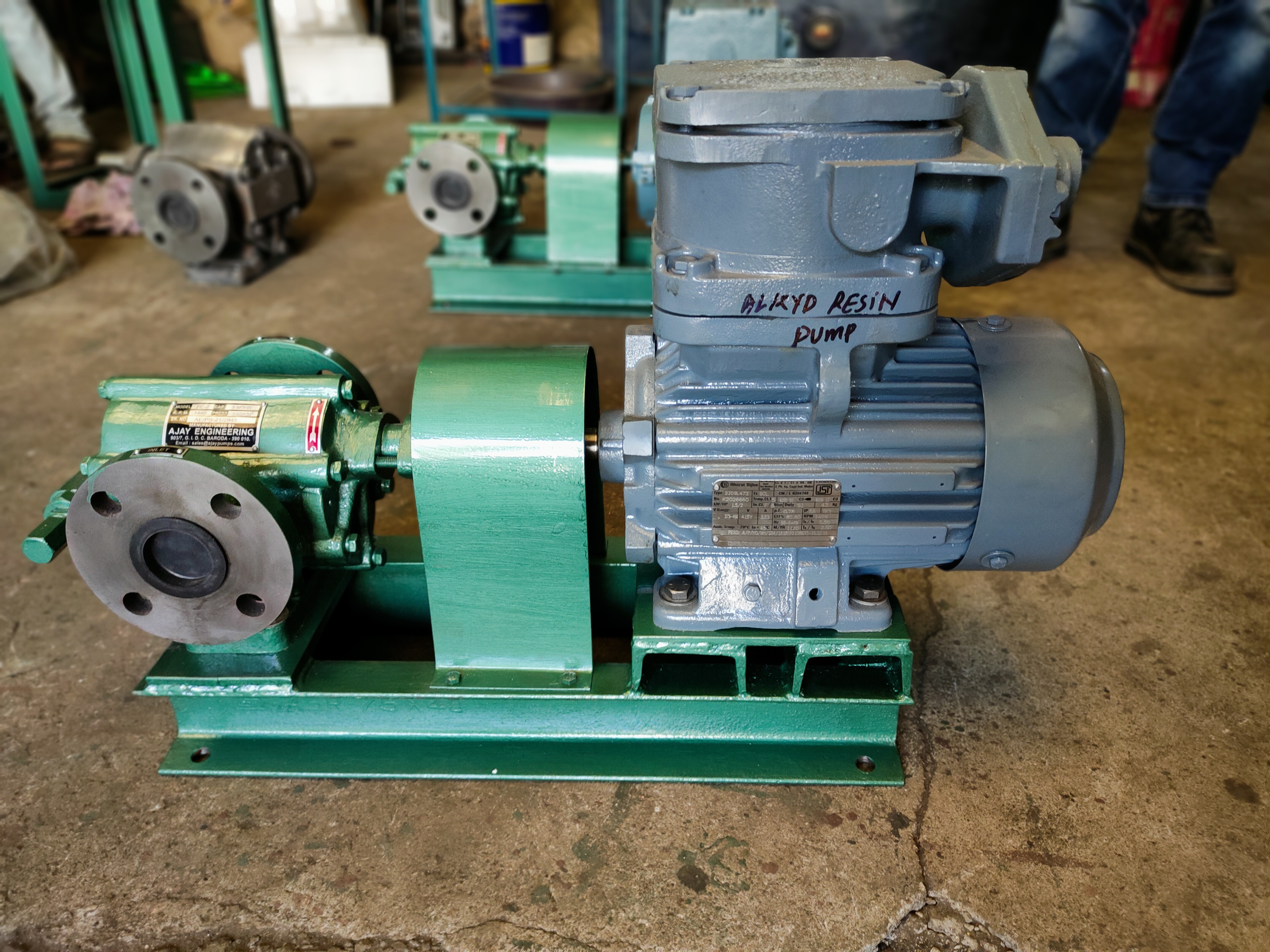

Rotary Transfer Gear Pumps

Our organization is a reputed member of Vadodara Chamber of Commerce and Industry (VCCI), instrumental in manufacturing, exporting and supplying a superlative quality of Rotary Transfer Gear Pumps. These pumps have an optimum RPM of 1500. We offer these pumps in both foot as well as trolley mounted assembly. Diesel engine driven, bodies of these pumps are made using graded cast iron. Adding to this, we have been offering spur, single helical as well as herringbone type gear in these Rotary Transfer Gear Pumps.

Products Features:

- Optimum performance

- Longer service life

- Accurate operational efficiency

- Minimal service life

General Specification:

- Type Of Drive : Directly Coupled To Ac Induction Motor / Diesel Engine Driven.

- Gears & Shafts : En-24 Harden & Ground.

- Sealing System : Mechanical Seal System / Oil-Seal System / Gland Packing System.

- Pressure Relief Valve : Externally Adjustable Integral Pressure Relief Valve.

- Bearing Type : Deep Groove Ball Bearings (4 Nos.) / Bi-Metallic Bronze Bushes (4 Nos.)

Products Technical Specification:

| Model | PORT OPTIONS | CAPACITY in Ltr/min (LPM) @ 1500 RPM | Recommended Horse-Power (hp) at Different Pressures | |||||

| Suction & Discharge (BSP Threaded Ends) |

Suction & Discharge (Flanged Ends) |

At 50 P.S.I. (H.P.) |

At 100 P.S.I. (H.P.) |

At 200 P.S.I. (H.P.) |

At 300 P.S.I. (H.P.) |

At 500 P.S.I. (H.P.) |

||

| GB-1 | " x " | --- | 30 | 1 | 1.5 | 3 | 5 | 7 |

| GB-2 | 1" x 1" | 1" x 1" | 40 | 1 | 2 | 5 | 5 | 10 |

| GB-3 | 1" x 1" | 1" x 1" | 50 | 1.5 | 3 | 5 | 7.5 | 10 |

| GB-4 | 1" x 1" | 1" x 1" | 60 | 1.5 | 3 | 5 | 7.5 | 15 |

| GB-5 | 1" x 1" | 1" x 1" | 70 | 1.5 | 3 | 7.5 | 10 | 15 |

| GC-1 | 1" x 1" | 1" x 1" | 80 | 2 | 5 | 7.5 | 12.5 | 15 |

| GC-2 | 1" x 1" | 1" x 1" | 100 | 2 | 5 | 10 | 15 | 20 |

| GC-3 | 2" x 2" | 2" x 2" | 150 | 3 | 7.5 | 12.5 | 15 | 25 |

| GC-4 | 2" x 2" | 2" x 2" | 200 | 5 | 5 | 10 | 15 | 30 |

| GC-5 | 2" x 2" | 2" x 2" | 250 | 5 | 7.5 | 12.5 | 15 | 30 |

| GD-1 | 2" x 2" | 2" x 2" | 300 | 7.5 | 7.5 | 15 | 25 | --- |

| GD-2 | 3" x 3" | 3" x 3" | 400 | 7.5 | 12.5 | 20 | --- | --- |

| GD-3 | 3" x 3" | 3" x 3" | 500 | 7.5 | 15 | 25 | --- | --- |

| GD-4 | --- | 4" x 4" | 1000 | 15 | 30 | 60 | --- | --- |

| GD-5 | --- | 4" x 4" | 1500 | 20 | 40 | 75 | --- | --- |

| GD-6 | --- | 6" x 6" | 3000 | 30 | 60 | --- | --- | --- |

Durability Meets Performance

Engineered with cast iron and a sturdy diaphragm structure, these gear pumps provide exceptional resilience in challenging agricultural environments. The blue finish enhances visibility and protection, while the robust design ensures uninterrupted diesel transfer for essential farm machinery and irrigation systems.

Expertise in Manufacturing and Export

As a leading exporter and supplier in India, we maintain high standards in production and quality control for rotary gear pumps. This ensures our products consistently deliver superior performance, safety, and reliability explored in global markets.

FAQs of Rotary Transfer Gear Pumps:

Q: How does a diaphragm rotary transfer gear pump operate for diesel fuel transfer?

A: The diaphragm gear pump utilizes a rotating gear mechanism to transfer diesel fuel efficiently. The diaphragm helps isolate the fuel and provides steady flow while minimizing leakage and maintaining consistent pressure, essential for agricultural machinery.Q: What makes cast iron an ideal material for these gear pumps?

A: Cast iron offers remarkable durability, resistance to corrosion, and strength under high pressure. These properties make it an excellent choice for agricultural environments, where pumps are exposed to harsh conditions and require long-lasting operation.Q: When should Rotary Transfer Gear Pumps be used in agriculture?

A: These pumps are best employed when frequent or large-scale diesel fuel transfers are neededsuch as during refueling of tractors, irrigation pumps, or other farming equipment. Their design supports continuous operation and high reliability in demanding situations.Q: Where are these pumps commonly installed within agricultural setups?

A: Typically, rotary transfer gear pumps are installed near fuel storage tanks or directly on agricultural machinery. Their sturdy construction enables outdoor and indoor use, adapting to various site requirements on farms and large agricultural facilities.Q: What are the key steps in the process of using this pump for diesel transfer?

A: Fuel transfer involves connecting the pump securely to the fuel source and destination, activating the rotary mechanism, and utilizing the diaphragm feature to control pressure and flow rates. Regular maintenance is recommended to ensure optimal performance.Q: How does using a rotary gear pump benefit agricultural diesel handling?

A: These pumps provide precise control over fuel transfer, minimize wastage and spills, and enhance safety for operators. Their efficient operation reduces downtime, supporting productivity and cost-effectiveness in agricultural workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email