Molasses Pump

Product Details:

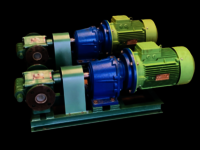

- Theory Rotary Pump

- Inlet/Outlet 1

- Flow Rate 1 KLPH to 50 KLPH

- Head Size 50 Meters

- Usage Industrial

- Material Cast Iron

- Structure Gear Pump

- Click to View more

Molasses Pump Price And Quantity

- 1 Piece

- 15000.00 INR/Piece

Molasses Pump Product Specifications

- Gland Packing, Oil Seal

- Gear Pump

- Medium Pressure

- Other

- 1

- 1 KLPH to 50 KLPH

- Rotary Pump

- Cast Iron

- 50 Meters

- Blue and Golden

- Industrial

- Electric

Molasses Pump Trade Information

- VADODARA

- Cash in Advance (CID)

- 50 Piece Per Month

- 7 Days

- Contact us for information regarding our sample policy

- Standard Box Packing

- Asia

- All India, Gujarat, Daman and Diu, Himachal Pradesh, Karnataka, Odisha, , Manipur, Dadra and Nagar Haveli, Rajasthan, Goa, Haryana, Central India, West India, Sikkim, Uttar Pradesh, Telangana, Chandigarh, Lakshadweep, Mizoram, Chhattisgarh, South India, Arunachal Pradesh, West Bengal, East India, Maharashtra, Delhi, Punjab, Pondicherry, Andhra Pradesh, Tripura, Bihar, Jharkhand, Madhya Pradesh, Andaman and Nicobar Islands, North India, Tamil Nadu, Meghalaya, Nagaland, Kerala, Assam, Uttarakhand, Jammu and Kashmir

- ISO , GST Verified

Product Description

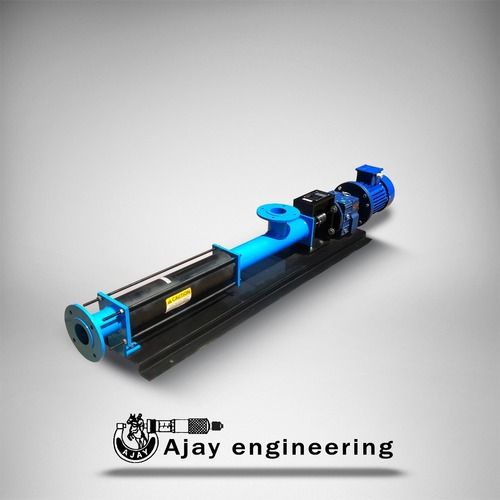

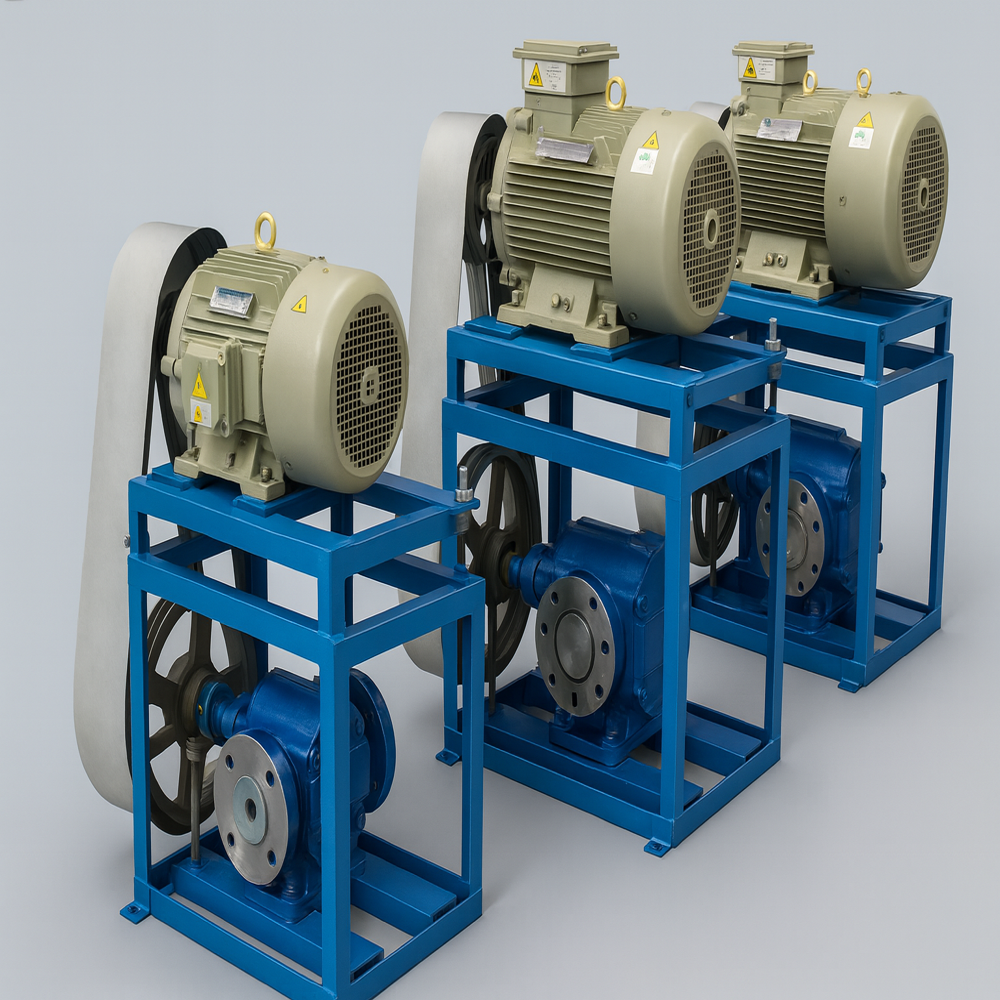

Ajay Engineering molasses pumps are specially designed positive-displacement and centrifugal pump configurations for handling high-viscosity fluids such as molasses, syrup, treacle, and other heavy sugar solutions. Available in horizontal and vertical layouts, our pumps feature gentle handling to prevent shear and crystallization, wide clearances for solids and fibers, and food-grade materials where required.

Key design highlights:

- Smooth flow paths to reduce clogging and product degradation.

- Heavy-duty bearings and seals for long life in abrasive, sticky media.

- Modular construction for quick servicing and spare parts interchangeability.

- Optional heating jackets, stainless steel wetted parts and hygienic finishes for food applications.

Core features & benefits

- High viscosity handling: Engineered clearances and rotor/stator designs to pump molasses up to high centipoise ranges without loss of efficiency.

- Corrosion & wear resistance: Stainless steel (SS304/SS316) and special alloy options for wetted parts to resist sugar, organic acids and abrasive solids.

- Low shear operation: Gentle pumping action preserves product quality (important for syrups, enzyme solutions and food applications).

- Easy maintenance: Cartridge seals, split casings and accessible bearing housings simplify downtime and reduce maintenance costs.

- Heating jacket option: Prevents crystallization in cold environments maintains viscosity and pumpability.

- Customizable: Multiple drive options (electric motor, gearbox, couplings), flange sizes, and seals (mechanical, gland or aseptic).

- Energy efficient designs: Optimized impeller/rotor geometry reduces power draw and operating expense.

- Safety & compliance: Food-grade finishes and materials available; designed to meet hygienic and industry standards on request.

Typical applications

- Sugar mills molasses transfer, blending and storage feed.

- Distilleries molasses feeding to fermenters and evaporators.

- Confectionery and syrup production dosing and transfer.

- Breweries and beverage plants viscous adjuncts and syrups.

- Chemical and fertilizer industries viscous by-products and slurries.

- Tank unloading, tanker transfer and batching systems.

- Any process requiring hygienic handling of sticky, viscous fluids.

Technical specifications

Note: Provide model-specific values to buyers. Below are common ranges used for molasses pumps; Ajay Engineering offers tailored models within these ranges.

Why choose Ajay Engineering

- Decades of specialized experience: Ajay Engineering has been a pioneer in molasses and viscous-fluid pumping solutions, combining traditional craftsmanship with modern manufacturing.

- Purpose-built designs: Every pump is engineered to the clients fluid properties - viscosity, solids content, temperature and shear sensitivity.

- After-sales support & spares: Rapid spare part supply, retrofit kits and field service reduce downtime.

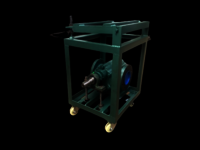

- Custom engineering: We provide turnkey solutions - pump package, control, piping layout and skid mounting.

- Quality & inspection: Each unit undergoes dimensional checks, hydrostatic & performance testing before dispatch.

FAQs

What types of molasses pumps do you supply?

We supply rotary lobe, progressive cavity, peristaltic and centrifugal pumps configured for high-viscosity molasses handling.

Can these pumps handle solids and fibers in molasses?

Yes ,selected models have large clearances and solids-handling rotors designed to pass fibers and crystals.

Do you offer food-grade or sanitary finishes?

Yes , wetted parts in SS304/SS316 with hygienic surface finishes and tri-clamp connections are available.

Is heating available to prevent crystallization?

Heating jackets and trace heating options are available for models where temperature control is required.

What information do you need to recommend a pump?

Typical requirements: fluid viscosity, temperature, flow rate, head, solids content, and duty cycle. (Ajay Engineering can assist with fluid testing.)

Do you provide installation and commissioning?

Yes , we offer field support for installation, commissioning and operator training.

What warranty and spares support do you offer?

Standard warranty period with extended warranty options and fast-moving spare parts inventory for critical components.

Can you supply pump skid packages?

Yes - we can deliver complete pump skid packages including piping, instrumentation and control panels.

Are there low-shear options for sensitive products?

Progressive cavity and peristaltic pumps provide low-shear transfer ideal for shear-sensitive syrups and enzymes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+