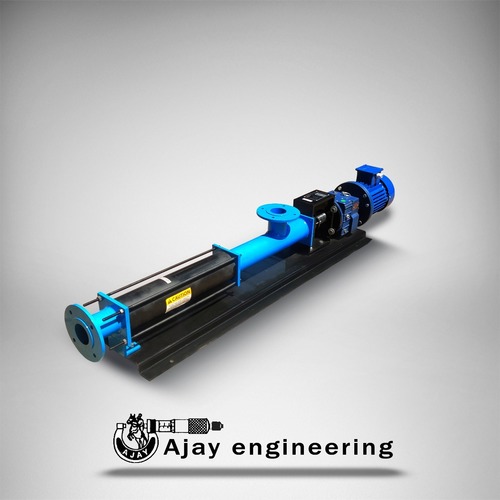

Screw Pump

22000 INR/Number

Product Details:

- Theory Other

- Control System Manual / Automatic (optional)

- Frequency 50 Hz

- Voltage 230/415 V

- Head Size Up to 24 Bar

- Max Suction Up to 8 meters

- Mounting Type Baseplate or foundation mounted

- Click to View more

X

Screw Pump Price And Quantity

- 1 Number

- 22000 INR/Number

Screw Pump Product Specifications

- Low

- Screw Pump

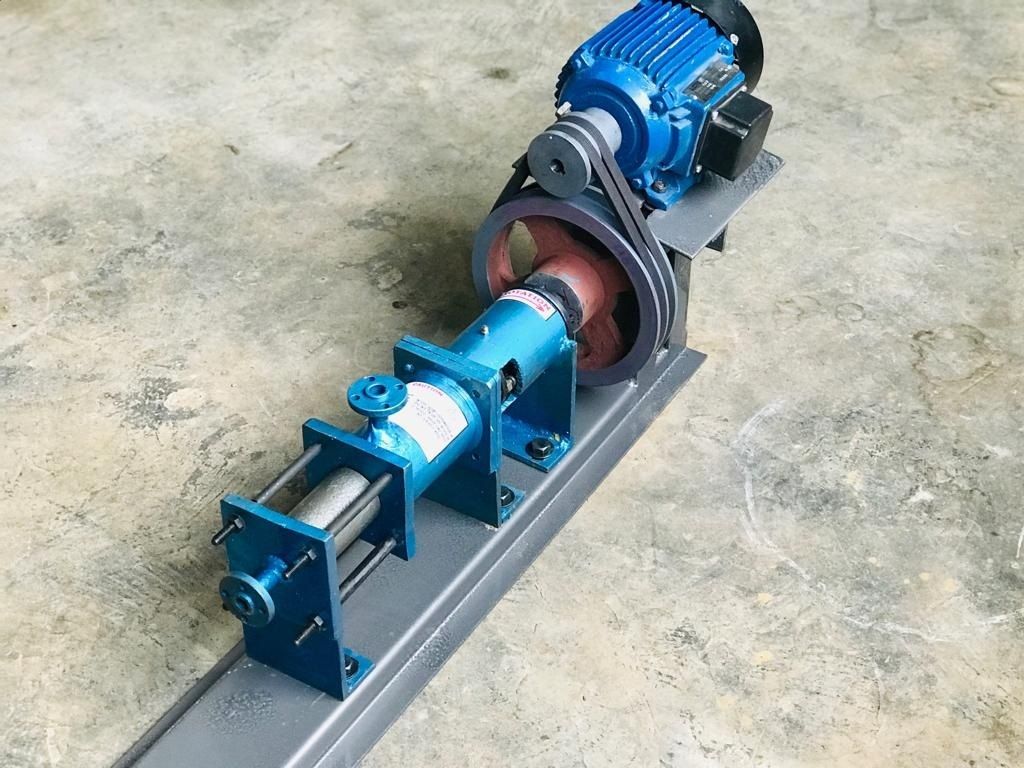

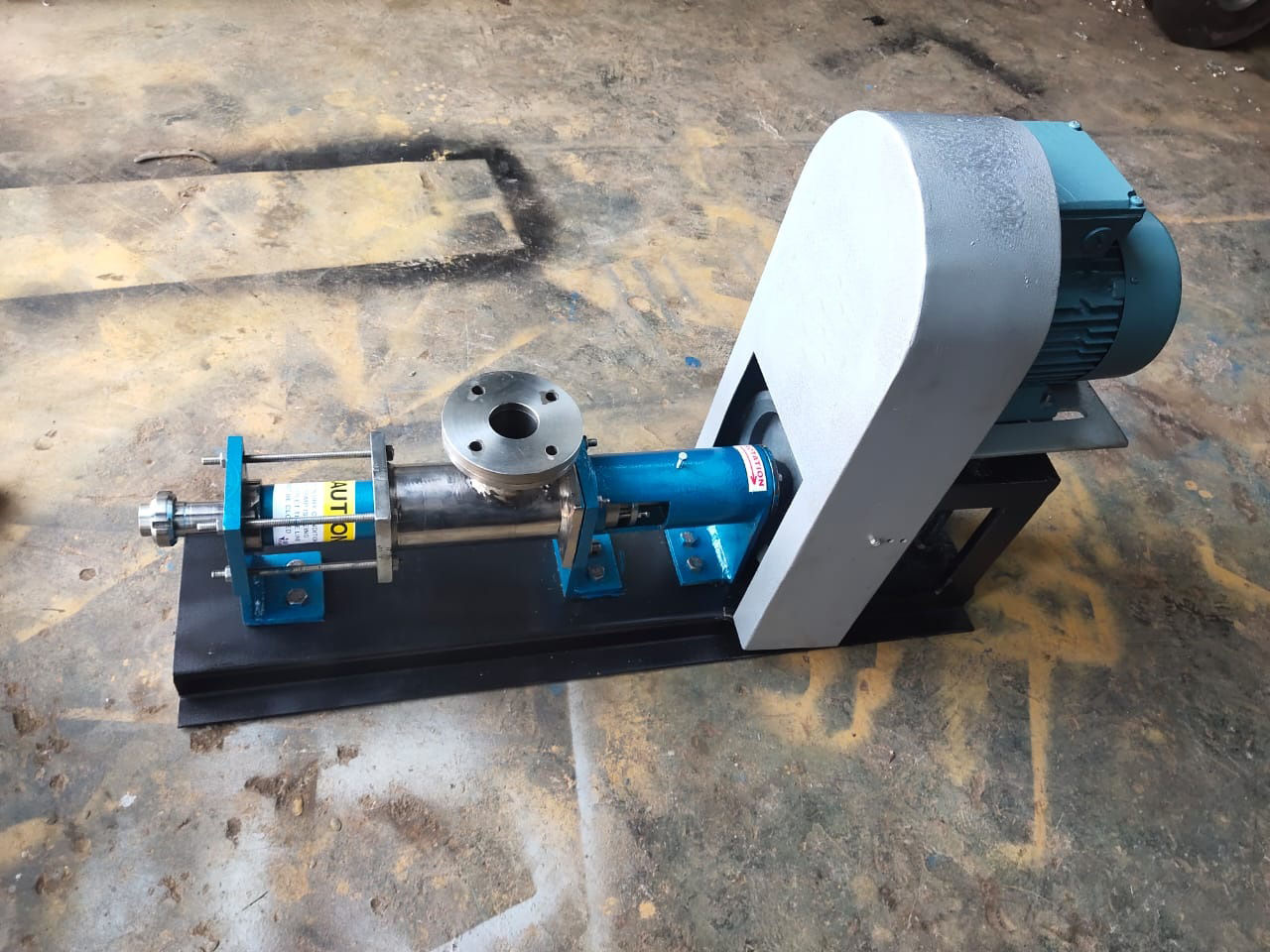

- Single screw and multi screw available

- 1 M3 to 100 M3

- 960-1440 RPM

- PUMP

- As per model specification

- Corrosion-proof, leak free, easy maintenance

- Up to 24 Bar

- 1 M3 to 100 M3/hr

- Up to 8 meters

- Baseplate or foundation mounted

- As per requirement (customizable)

- Up to 120C

- 230/415 V

- Up to 24 Bar

- Self Priming

- ISI/ISO standard compliant

- Up to 24 Bar

- Electric

- Other

- Positive Suction

- Gland Packing & Mechanical Seal

- Oil, sludge, slurry, viscous liquids and chemical transfer

- Other

- Manual / Automatic (optional)

- Electric

- 50 Hz

Screw Pump Trade Information

- Vadodara

- 1000 Number Per Month

- 7 Hours

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packing

- Middle East, Asia, Africa

- All India, Himachal Pradesh, South India, Gujarat, Punjab, Nagaland, Dadra and Nagar Haveli, Telangana, Chhattisgarh, Mizoram, Andhra Pradesh, East India, West Bengal, Tamil Nadu, North India, Assam, Pondicherry, Meghalaya, Jammu and Kashmir, Uttarakhand, Karnataka, Tripura, Delhi, Jharkhand, Madhya Pradesh, Rajasthan, Chandigarh, Uttar Pradesh, Manipur, Andaman and Nicobar Islands, , Odisha, Kerala, Sikkim, Daman and Diu, Goa, Arunachal Pradesh, West India, Haryana, Bihar, Lakshadweep, Maharashtra, Central India

Product Description

Ajay Series Pumps are designed for solid & liquid Mixing and Transfer, Fluids Handled are Liquid Manure, Molasses, Process Water, Ground Bio Waste, Food Waste, Oil Sludge, Effluent Sludge, Acids, Gums, Acrylic Ceramic, Chemical Slurry, Magma, Solvents, Vegetable oil, Soya Lecithin,Apple Pulp, Beer, Mango, Butter Oil, Glucose, Fruit Pulp, Yogurt etc.

Specification

|

Material |

Mild Steel |

|

Max Flow Rate |

100 M3 |

|

Pressure |

35 Bar |

Versatile Fluid Handling

Our screw pumps handle a broad spectrum of viscositiesideal for lubricating oils, chemicals, and other industrial liquids. With flow rates ranging from 1 M3 to 100 M3, theyre suitable for both small- and large-scale operations. Choose between flanged or threaded connections to seamlessly fit your piping system, while optional seal cooling increases performance longevity.

Durable Materials for Demanding Applications

We utilize high-grade SS 304/316 for shafts and premium elastomers like nitrile, rubber, EPDM, or neoprene for stators to match your liquid requirements. This ensures corrosion resistance, durability, and optimized service life. Our pumps are protected with IP55-rated motors, supporting reliable operation in temperatures up to 50C.

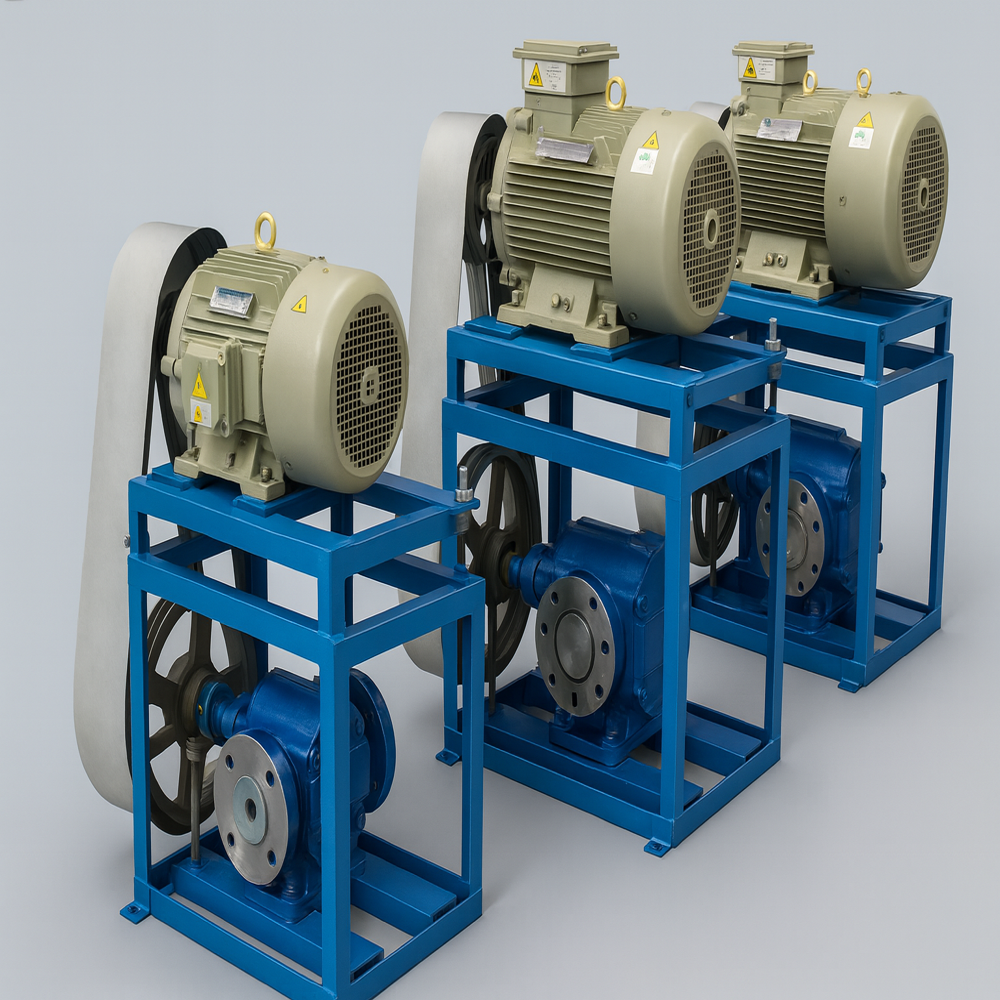

Flexible Installation and Export Support

As a leading manufacturer, supplier, and exporter based in India, we provide various mounting optionsdirect coupled or belt drivencatering to diverse installation needs worldwide. Our support extends to technical guidance and export logistics, ensuring safe delivery and seamless integration into your industrial workflow.

FAQs of Screw Pump:

Q: How does the screw pump accommodate different viscosity ranges?

A: Our screw pumps are engineered to handle viscosities up to 100,000 cst, thanks to robust construction and selectable stator materials such as nitrile, rubber, EPDM, or neoprene. This design enables efficient pumping of both thin and highly viscous fluids without compromising performance.Q: What are the available connection types, and which should I choose for my system?

A: We offer flanged and threaded connection options. Flanged connections provide secure, leak-resistant integration for heavy-duty and large-scale systems, while threaded connections suit smaller setups where quick installation or disassembly is needed. Selection depends on your piping infrastructure and process requirements.Q: When is seal cooling recommended for the screw pump?

A: Seal cooling is recommended when pumping abrasive, high-temperature, or viscous liquids, or in environments where prolonged operation may cause seal overheating. It helps extend seal life and enhance operational reliability, and is available as an optional feature for our pumps.Q: Where can these screw pumps be installed?

A: These pumps are suitable for installation across a wide range of industriessuch as oil, chemical, and food processingboth indoors and outdoors, provided ambient temperatures remain below 50C. Their universal mounting options allow for flexible placement at your facility.Q: What is the process for selecting the right shaft and stator material?

A: Material selection depends on the nature of the liquid being pumped. Stainless steel 304 or 316 shafts are chosen for their corrosion resistance, while stators in nitrile, rubber, EPDM, or neoprene are matched based on chemical compatibility and operating conditions to ensure peak performance.Q: How do screw pumps benefit industrial fluid handling operations?

A: Screw pumps are valued for their ability to handle high-viscosity fluids efficiently, provide constant flow rates, and reduce pulsation. This leads to reliable, low-maintenance operation and improved process efficiency in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email