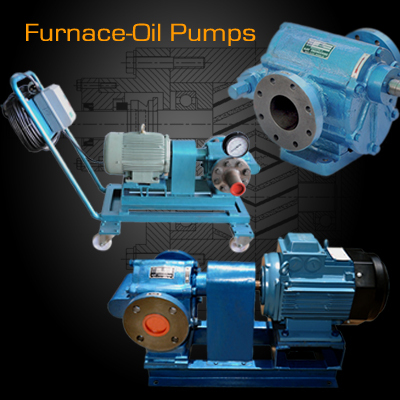

Furnace Oil Transfer Pump

Product Details:

- Flow Rate 20 LPM to 2000 LPM

- Inlet/Outlet 1/2" to 6"

- Usage Industrial

- Theory Rotary Pump

- Color Blue

- Material Cast Iron

- Structure Gear Pump

- Click to View more

Furnace Oil Transfer Pump Price And Quantity

- 12000 INR/Piece

- 1 Number

Furnace Oil Transfer Pump Product Specifications

- Rotary Pump

- High Pressure

- Blue

- Electric

- Gear Pump

- Other

- Mechanical Seal, Oil Seal, Gland Packing

- 20 LPM to 2000 LPM

- Cast Iron

- 1/2" to 6"

- Self Priming

- Industrial

- Other

Furnace Oil Transfer Pump Trade Information

- Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID)

- 50 Number Per Month

- 3-4 Week

- Middle East, Asia, Africa

- All India

Product Description

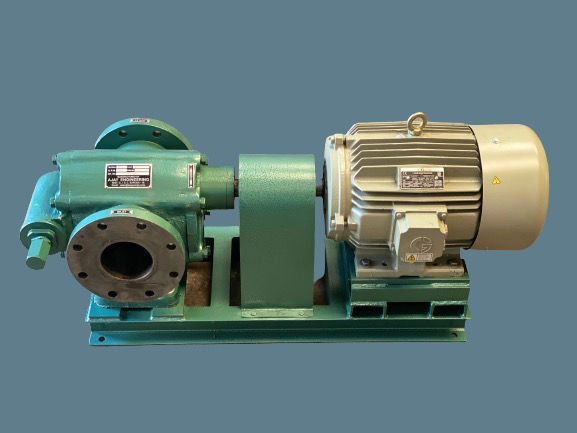

Leveraging on our thirty four years of expertise, we have been able to manufacture, export and supply a superior grade of Furnace Oil Transfer Pump. This pump is made using meshing of gears so as to pump the fluid by displacement. Owing to its optimum displacement power, these pumps are used in transferring different grades of oils and chemicals such as diesel oils, fuel oils and various others. Additionally, our offered pumps are quality approved at various levels of manufacturing. Furnace Oil Transfer Pump offered by us is known for the listed quality features:

- Smooth operation

- Easy handling

- Simple design

- Sturdiness

Product details

|

Frequency |

50 hz |

|

Brand |

Ajay Engineering |

|

Material |

Mild Steel |

|

Motor Speed |

1440 RPM |

|

Voltage |

220 v |

|

Discharge |

20 LPM to 2000 LPM |

Robust Industrial Applications

Engineered for the demanding needs of industrial environments, this furnace oil transfer pump is suitable for seamless movement of oils in manufacturing plants, chemical processing units, and other heavy-duty facilities. Its durable construction supports continuous operation under high pressure, ensuring reliable processes where efficiency is critical.

Versatile Performance Range

With a flow rate spectrum spanning from 20 LPM up to 2000 LPM and accommodating multiple inlet/outlet diameters, this pump can be tailored to a wide variety of installation requirements. Its self-priming feature further simplifies integration into both new and existing oil transfer systems, providing flexibility and adaptability.

FAQs of Furnace Oil Transfer Pump:

Q: How does the furnace oil transfer pump achieve self-priming operation?

A: The pumps gear structure and rotary theory enable it to draw oil automatically from the source, eliminating the need for manual priming. This self-priming mechanism ensures quick startup and reduces downtime during installation or maintenance.Q: What are the main benefits of using a mechanical, oil, or gland packing seal for this pump?

A: Users can select from mechanical seal, oil seal, or gland packing options depending on their applications needs. Each type provides reliable leak prevention, compatibility with different oil viscosities, and ease of maintenance, ensuring improved operational efficiency and longevity.Q: When should a high-pressure, self-priming furnace oil pump be used?

A: These pumps are recommended when dealing with high-viscosity oils, long transfer distances, or systems requiring consistent, high-flow output. Their self-priming and robust pressure design make them ideal for challenging industrial environments where downtime is not acceptable.Q: Where are these pumps typically installed in industrial settings?

A: These pumps are commonly installed at oil storage facilities, manufacturing plants, power stations, and sites needing efficient furnace oil transfer. Their flexible inlet/outlet sizing allows easy integration with existing pipelines and equipment.Q: What is the process for installing the furnace oil transfer pump?

A: Installation involves mounting the pump securely, connecting the inlet and outlet pipes (1/2" to 6"), and wiring it to a compatible electric source. Choosing the appropriate sealing type and ensuring proper alignment are crucial for optimal operation.Q: How does the cast iron material benefit high-pressure industrial oil transfer?

A: Cast iron construction provides excellent strength and corrosion resistance, ensuring the pump can withstand prolonged exposure to harsh industrial environments and abrasive oil types, thus enhancing equipment reliability.Q: What makes this pump suitable for export and supply across India and beyond?

A: Manufactured to international standards and rigorously tested, these pumps feature adaptability, durability, and reliable performance, making them highly sought after by global and domestic industries seeking efficient oil transfer solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+