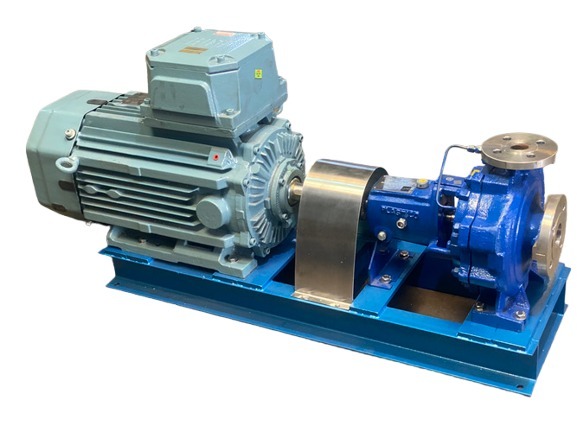

Centrifugal Process Pumps

उत्पाद विवरण:

- इनलेट/आउटलेट 1" to 8"

- फ्लो रेट 100 LPM to 4000 LPM

- थ्योरी

- स्ट्रक्चर

- पावर

- फ्यूल टाइप

- प्रेशर

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- 100 LPM to 4000 LPM

- Mechanical Seal

- 1" to 8"

व्यापार सूचना

- , ,

उत्पाद वर्णन

The Ajay Engineering Centrifugal Process Pump operates on the centrifugal principle, converting mechanical energy from a motor into kinetic energy in the fluid using an impeller. The fluid is directed into the pump impeller along or near the rotating axis and discharged by centrifugal force through the impellers vane tips.

These pumps are designed to handle clean, viscous, and corrosive liquids with high efficiency. They are available in various materials of construction such as Cast Iron, Stainless Steel (SS-304/SS-316), Alloy 20, and Hastelloy, making them suitable for a wide range of industrial applications.

Ajay Engineerings Centrifugal Process Pumps are engineered for long service life, minimal maintenance, and energy efficiency, ensuring consistent performance in all operating environments.

Key Features & Benefits

- High Efficiency Design: Optimized impeller and casing geometry for maximum flow and minimum power consumption.

- Robust Construction: Available in CI, SS, and special alloys for superior corrosion and wear resistance.

- Smooth & Vibration-Free Operation: Precision-balanced rotating parts ensure quiet performance.

- Easy Maintenance: Simple back-pullout design allows easy dismantling without disturbing pipe connections.

- Wide Operating Range: Handles varying viscosities, temperatures, and discharge pressures.

- Leak-Proof Sealing: Available with high-quality mechanical seals or gland packing.

- Long Service Life: Heavy-duty bearings and shafts ensure durability under continuous duty.

- Custom-Built Solutions: Designed to match specific process and material requirements.

- Energy Efficient: Low NPSH requirement and high overall efficiency reduce operational costs.

Available with Base Frame or Monoblock Options: Compact and convenient installation.

Applications

Ajay Engineering Centrifugal Process Pumps are used across a wide range of industries, including:

- Chemical & Process Industry: Acids, alkalis, solvents, caustic soda, and other corrosive liquids.

- Pharmaceutical & Biotechnology: Purified water, chemical solutions, and process fluids.

- Food & Beverage Industry: Edible oils, syrups, juices, and water-based liquids.

- Petrochemical & Refinery Plants: Hydrocarbons, lubricating oils, and light chemicals.

- Water Treatment & Utility Plants: Pumping of clear water, effluents, and cooling liquids.

- Paints, Dyes & Adhesive Industry: Paints, inks, pigments, and polymer solutions.

Technical Specifications

Why Choose Ajay Engineering

- Industry Pioneer: With years of proven excellence, Ajay Engineering stands as a leader in centrifugal pump technology.

- Precision Engineering: Each pump is CNC-machined for accuracy, performance, and reliability.

- Custom Design Expertise: Pumps are tailored to suit your process, flow, and fluid requirements.

- Quality You Can Trust: Every pump undergoes rigorous testing for flow, pressure, and durability.

- Energy-Efficient Performance: Optimized hydraulics reduce power consumption and operational cost.

- Comprehensive Support: Technical consultation, after-sales service, and spare part availability.

- Proven Track Record: Trusted by top industries in India for reliability and long-term performance.

Ajay Engineering - Setting the Benchmark in Centrifugal Process Pump Performance and Reliability.

- centrifugal process pump manufacturer

- Ajay Engineering centrifugal pump

- stainless steel process pump

- industrial centrifugal pump India

- chemical process pump manufacturer

- SS-316 centrifugal pump

- high pressure process pump

- water and chemical transfer pump

- monoblock centrifugal pump

- energy efficient centrifugal pump

Frequently Asked Questions (FAQs)

Q1. What is a Centrifugal Process Pump?

A centrifugal process pump transfers liquid by converting rotational kinetic energy into hydrodynamic energy using an impeller, suitable for continuous fluid handling.

Q2. Why choose Ajay Engineerings Centrifugal Pumps?

Ajay Engineering is a pioneer in precision-engineered pumps offering reliable performance, superior efficiency, and robust construction.

Q3. Are these pumps suitable for corrosive liquids?

Yes, pumps are available in SS-304, SS-316, and special alloys for handling corrosive and chemical media.

Q4. Can these pumps handle high temperatures?

Yes, they can handle up to 200 deg C, ideal for hot fluid or chemical applications.

Q5. Do you offer customized designs?

Absolutely Ajay Engineering provides tailor-made centrifugal pumps as per capacity, material, and application requirements.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+