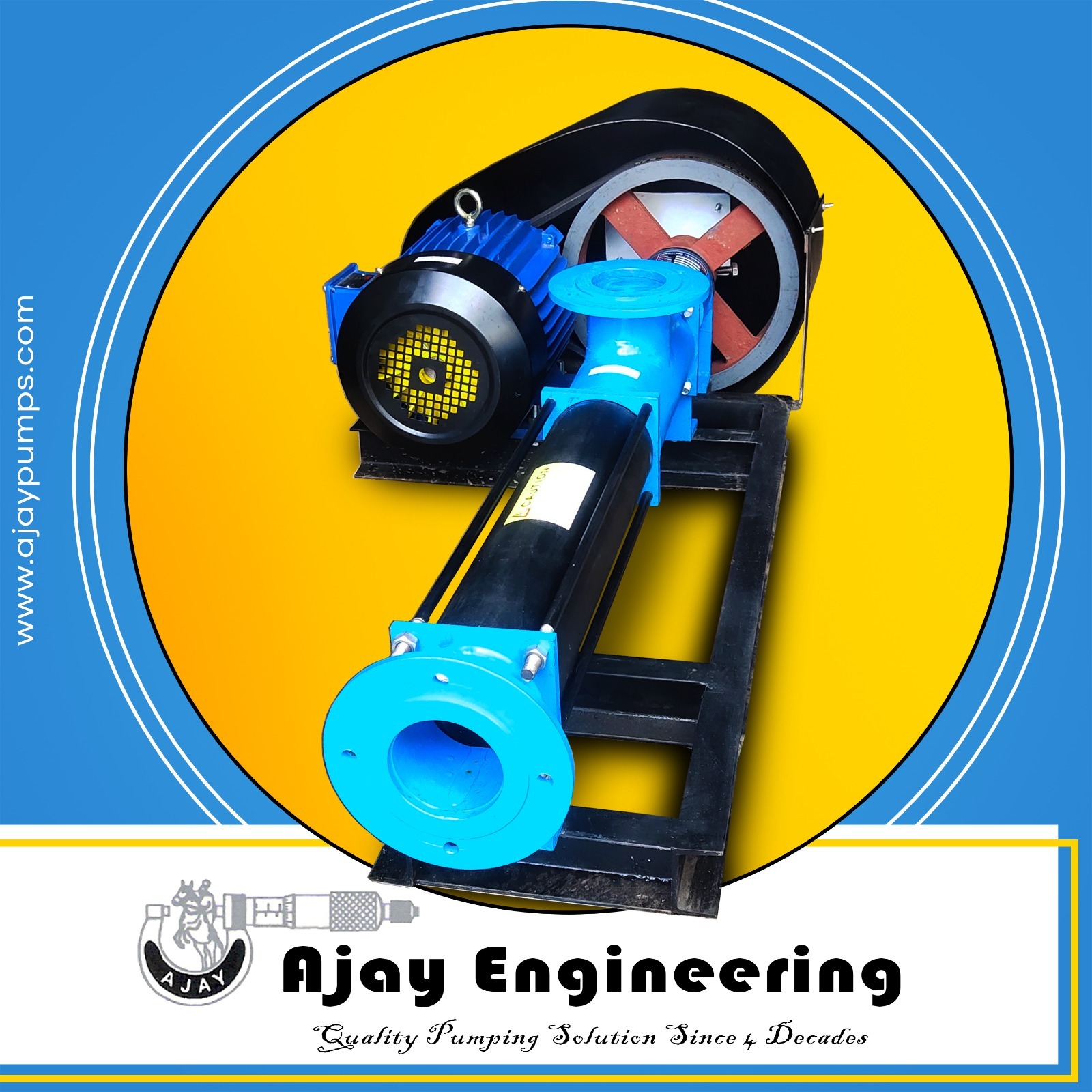

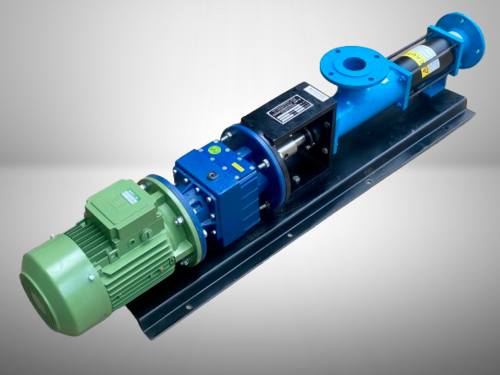

Single Screw Pump

Product Details:

- Discharge Pressure Up to 24 Bar

- Caliber DN25 to DN200

- Control System Manual/Automatic

- Speed 280 1450 RPM

- Head Size 6m to 240m

- Voltage 220V/380V/415V

- Theory Progressive Cavity

- Click to View more

Single Screw Pump Price And Quantity

- 1 Number

- 15000 INR/Number

Single Screw Pump Product Specifications

- 0.37 kW to 45 kW

- Up to 100 m/hr

- Up to 24 Bar

- DN25 to DN200

- Mechanical Seal / Gland Packing

- Manual/Automatic

- Industrial/Sludge Handling/Oil Transfer

- Positive Suction

- Self-Priming

- 280 1450 RPM

- 6m to 240m

- ISO/CE

- Progressive Cavity

- 220V/380V/415V

- Self-priming, Handles viscous fluids, Low pulsation

- Up to 150C

- DN25 to DN200

- 6m

- Single Screw

- 50 Hz/60 Hz

- Effluent, Sludge, Chemical, Oil, Food Processing

- Electric

- Single Screw Pump

- Cast Iron / SS 304 / SS 316

- Up to 24 Bar

- Base Mounted/Skid Mounted

- Low

- 0.1 m/hr to 100 m/hr

Product Description

we are passionate about providing cutting-edge solutions for your most challenging pumping needs. As a leading manufacturer of progressive cavity pumps (PCPs), we take pride in offering reliable, efficient, and innovative pumping systems for a wide range of industries.

We understand that every application has its own unique needs. That's why we offer a diverse range of PCPs, carefully engineered to handle viscous, abrasive, and shear-sensitive fluids with superior performance. Our commitment to quality and innovation ensures that our pumps deliver exceptional flow rates, efficient operation, and long-lasting durability.

Whether you require precise dosing for delicate food products, robust handling of abrasive slurries, or dependable operation in harsh environments, [Your Company Name] has the expertise and the PCP solution to meet your specific needs. We invite you to explore our portfolio and discover how our pumps can help you optimize your flow and achieve unmatched performance in your applications.

Rugged Construction and Versatile Material Choices

Choose from a selection of rotor (Alloy Steel, SS 304, SS 316) and stator (Nitrile Rubber, EPDM, Viton) materials to ensure compatibility with a broad range of aggressive or viscous fluids. The robust body options in Cast Iron or Stainless Steel provide corrosion resistance and durability in industrial environments.

Reliable and Efficient Fluid Handling

This single screw pump ensures smooth, self-priming operation with low pulsation, making it ideal for handling fluids up to 100,000 cSt viscosity. It accommodates capacities up to 100 m3/hr, head sizes to 240m, and discharge pressures to 24 Bar, delivering reliable performance for oil, effluent, sludge, and chemicals.

Simplified Maintenance and Installation

Built with a simple design for straightforward maintenance, the pump offers easy access to wearable components, reducing downtime. It supports horizontal or vertical mounting, manual or automatic control, and grease or oil lubrication for adaptability in various settings.

FAQ's of Single Screw Pump:

Q: How does the single screw pump handle highly viscous fluids?

A: Thanks to its progressive cavity design, the single screw pump efficiently transfers fluids with viscosities up to 100,000 cSt without significant pulsation or loss of performance, making it ideal for sludge, oil, and other thick materials.Q: What benefits does the pump's material options provide for different applications?

A: With rotors available in Alloy Steel, SS 304, or SS 316, and stators in Nitrile Rubber, EPDM, or Viton, the pump can be tailored for chemical compatibility, abrasion resistance, and high durability, ensuring suitability for a wide spectrum of fluids.Q: Where can this pump be installed, and what mounting types are supported?

A: The pump can be installed in both horizontal and vertical positions, and is available in base mounted or skid mounted configurations, offering flexibility for various industrial layouts and space requirements.Q: What is the typical process for maintaining this pump?

A: Routine maintenance involves inspecting and replacing the stator and rotor if needed, lubricating with either grease or oil, and checking seals. Its simple structure enables quick access and minimal downtime during servicing.Q: When should a gland packing seal be chosen over a mechanical seal?

A: Gland packing is often selected for applications with more abrasive fluids or when budget is a higher priority. Mechanical seals are preferable for higher pressures or when leakage control is critical, such as in hazardous fluid handling.Q: How does the pump ensure operational safety and equipment protection?

A: Featuring IP55 or IP65 protection class enclosures, the pump offers resistance to dust and water ingress, while its robust construction, sealed design, and surface finishes like painting or epoxy coating further enhance operational safety.Q: What industries and applications benefit most from this pump?

A: Industries such as wastewater treatment, oil and chemical processing, and food manufacturing benefit from the pump's ability to handle a variety of fluids, including effluent, sludge, oils, and delicate mixtures, due to its gentle, self-priming, and low-pulsation operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+