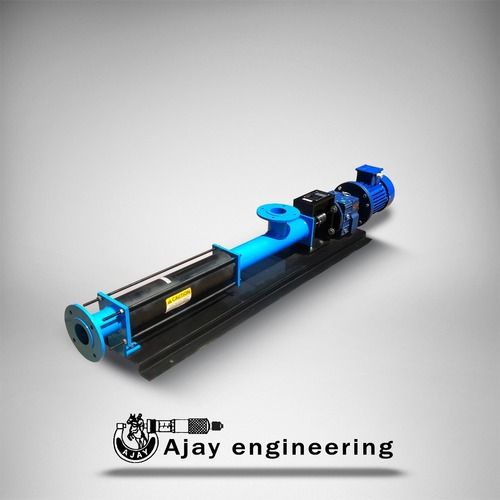

Molasses Dosing Pump

Product Details:

- Working Temperature 50 Celsius (oC)

- Voltage 415 Volt (v)

- Material SS

- Structure Other

- Usage Water, Food, Automobile

- Application Other

- Seals Type Gland Packing

- Click to View more

Molasses Dosing Pump Price And Quantity

- 20000.0 INR/Unit

- 1 Unit

Molasses Dosing Pump Product Specifications

- 50 Celsius (oC)

- Gland Packing

- SS

- Water, Food, Automobile

- Other

- 415 Volt (v)

- Other

Molasses Dosing Pump Trade Information

- Vadodara

- Cash in Advance (CID)

- 10 Unit Per Month

- 7 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Standard packing

- Asia

- Lakshadweep, Mizoram, Meghalaya, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Haryana, Manipur, Andhra Pradesh, Bihar, Madhya Pradesh, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Maharashtra, Himachal Pradesh, Jammu and Kashmir, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

Molasses Gear Pumps

AM-Series Classification

Established in the year 1980, ours is a well established organization engaged inmanufacturing, exporting and supplyinga superlative range of quality approvedMolasses Gear Pumps. These pumps are designed and developed using optimum grade material in our state-of-the-art manufacturing plant. Offered with vertical mounting, these pumps have optimum RPM rating. Adding to this, pumps offered by us have perfect liquid temperature and the pump body is made using high grade cat iron so as to ensure its longer life.Molasses Pumpsoffered by us is known for the following quality features:

- Designed for High Viscous Fluids

- V Belt Pulley System is Cost Effective and Capable of Operating at Low RPM.

- Flexible functioning is done by our Molasses Gear Pumps

- Provided Molasses Pumps having Robust construction

- Simple Belt Adjustment System.

- Pillow Block Bearing Support reduces shaft load and Increases Pump Life.

- Easy Maintenance.

General Specification:

- Pump Rpm : 350-500 Rpm.

- Mounting : Vertical Mounting.

- Optimum Liquid Temp. : 30o C To 80o C.

- Suction Condition : Flooded.

- Suction Foot-Valve : To Be Compulsorily Installed.

- Pump Drive : V-Belt Pulley Driven / Variable Speed Drive / In-Line Gearbox Driven.

- Pump Body & Covers : Graded Cast Iron.

- Gears & Shafts : En-24 Harden & Ground.

- Gear Type : Spur / Single Helical / Herringbone.

- Sealing System : Gland Packing System.

- Bearing Type : Bi-Metallic Bronze Bushes (4 Nos.)

Specification

|

Display Type |

NA |

|

Brand |

Ajay |

|

Head |

50 Mtrs |

|

Material |

Cast Iron |

|

Maximum Pressure |

20 Bar |

|

Installation / After Sales Service |

Provided |

|

Warranty Period |

12 Months |

|

I Deal In |

New Only |

|

Country of Origin |

Made in India |

Versatile Applications Across Industries

Engineered to serve water, food, and automobile industries, this molasses dosing pump delivers consistent performance under diverse operating conditions. Its compatibility with a range of fluids and robust construction make it ideal for environments where hygiene, durability, and precision are crucial.

Robust Construction and Advanced Sealing

Manufactured from stainless steel, the pump is built to resist corrosion, ensuring a long service life. The gland packing seal technology minimizes leaks and maintains operational efficiency, even when handling viscous substances like molasses at temperatures up to 50C.

FAQs of Molasses Dosing Pump:

Q: How is the molasses dosing pump installed and commissioned?

A: The pump should be installed on a level surface close to the application site. Ensure that electrical connections are made to a 415 Volt power supply, following safety guidelines. Commissioning involves priming the pump, setting flow rates, and verifying the gland packing for proper adjustment to prevent leaks.Q: What are the main benefits of using a stainless steel molasses dosing pump?

A: Stainless steel construction provides superior corrosion resistance, ensuring hygiene and extended durability. This makes the pump well-suited for water, food, and automobile industries, where strict material compatibility and longevity are required.Q: When should gland packing seals be checked or replaced?

A: Routine inspection of gland packing seals is recommended every three to six months, or sooner if there is evidence of leakage or performance decline. Timely replacement reduces maintenance costs and sustains pump efficiency.Q: Where can the molasses dosing pump be used effectively?

A: This pump is effective in locations requiring precise dosing of fluids, including food processing plants, water treatment facilities, and automotive manufacturing units. Its temperature and material tolerances make it versatile for a range of industrial settings.Q: What is the recommended process for dosing molasses using this pump?

A: Begin by setting the required dosing rate, ensuring the pump is primed with molasses. Monitor the flow and adjust the gland packing as needed to maintain consistent, leak-free operation at temperatures up to 50C.Q: How does the pump contribute to operational improvements for exporters, manufacturers, and suppliers in India?

A: The pumps durability, efficiency, and reliable sealing minimize downtime and maintenance, which improves productivity for exporters, manufacturers, and suppliers. Its compliance with industry standards also supports smooth export documentation and market acceptance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+