Molasses Transfer Pump

Product Details:

- Max Suction 1 Meter

- Color Blue

- Flow Rate 500 LPH to 50,000 LPH

- Usage Cattle Feed

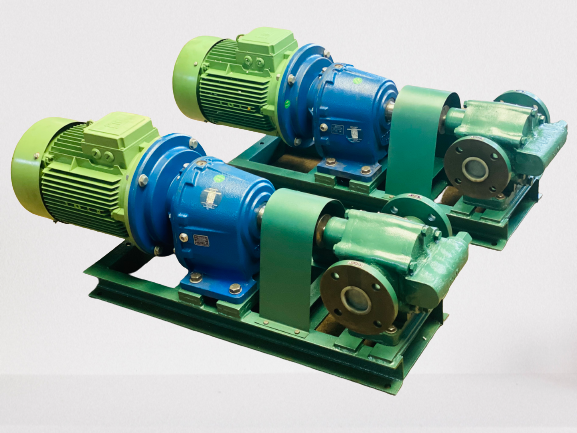

- Theory Rotary Pump

- Inlet/Outlet 1" x 1" to 6" x 6"

- Material Cast Iron

- Click to View more

Molasses Transfer Pump Price And Quantity

- 1 Number

- 20000.00 INR/Unit

Molasses Transfer Pump Product Specifications

- 1" x 1" to 6" x 6"

- Cast Iron

- Electric

- Self Priming

- 500 LPH to 50,000 LPH

- Blue

- 1 Meter

- Medium Pressure

- Gland Packing

- Cattle Feed

- Rotary Pump

- Gear Pump

Molasses Transfer Pump Trade Information

- Vadodara

- 50 Number Per Month

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packing

- All India, Gujarat, Uttar Pradesh, Jammu and Kashmir, Telangana, Haryana, North India, Karnataka, Goa, Arunachal Pradesh, Rajasthan, Bihar, Maharashtra, South India, Dadra and Nagar Haveli, Delhi, Nagaland, Andaman and Nicobar Islands, Chandigarh, Himachal Pradesh, Meghalaya, Odisha, Tamil Nadu, Assam, Andhra Pradesh, Daman and Diu, Manipur, Pondicherry, Chhattisgarh, West India, East India, Madhya Pradesh, Lakshadweep, Jharkhand, Central India, Punjab, Kerala, Uttarakhand, Tripura, West Bengal, Mizoram, Sikkim

Product Description

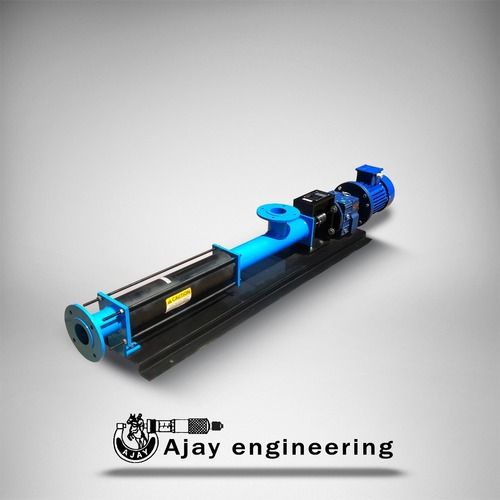

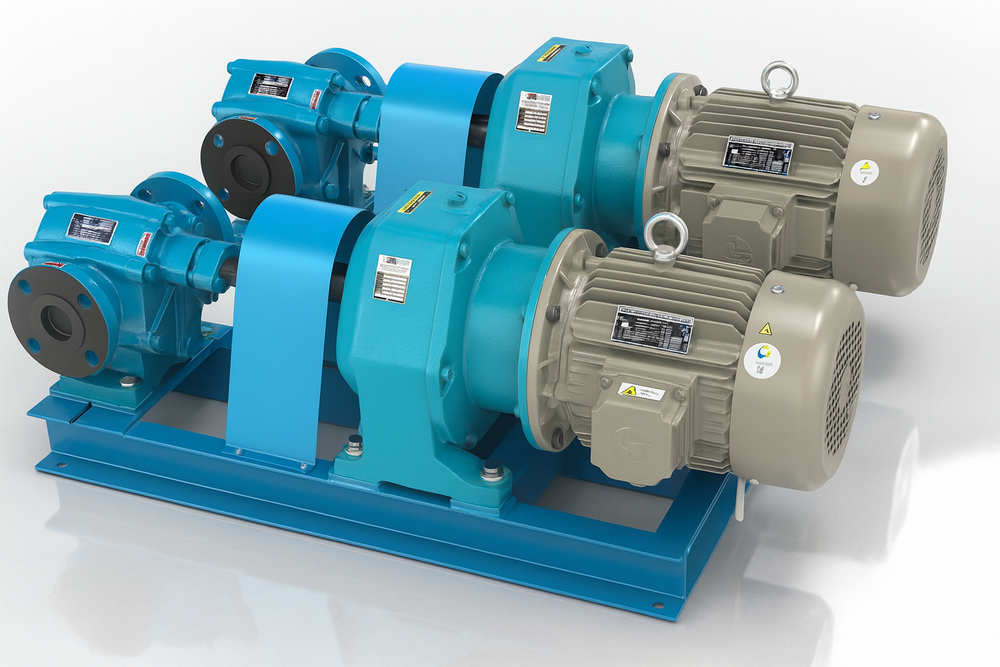

Ajay Engineering Molasses Transfer Pumps are specially designed for handling thick, viscous, and semi-solid materials that standard pumps cannot manage efficiently.

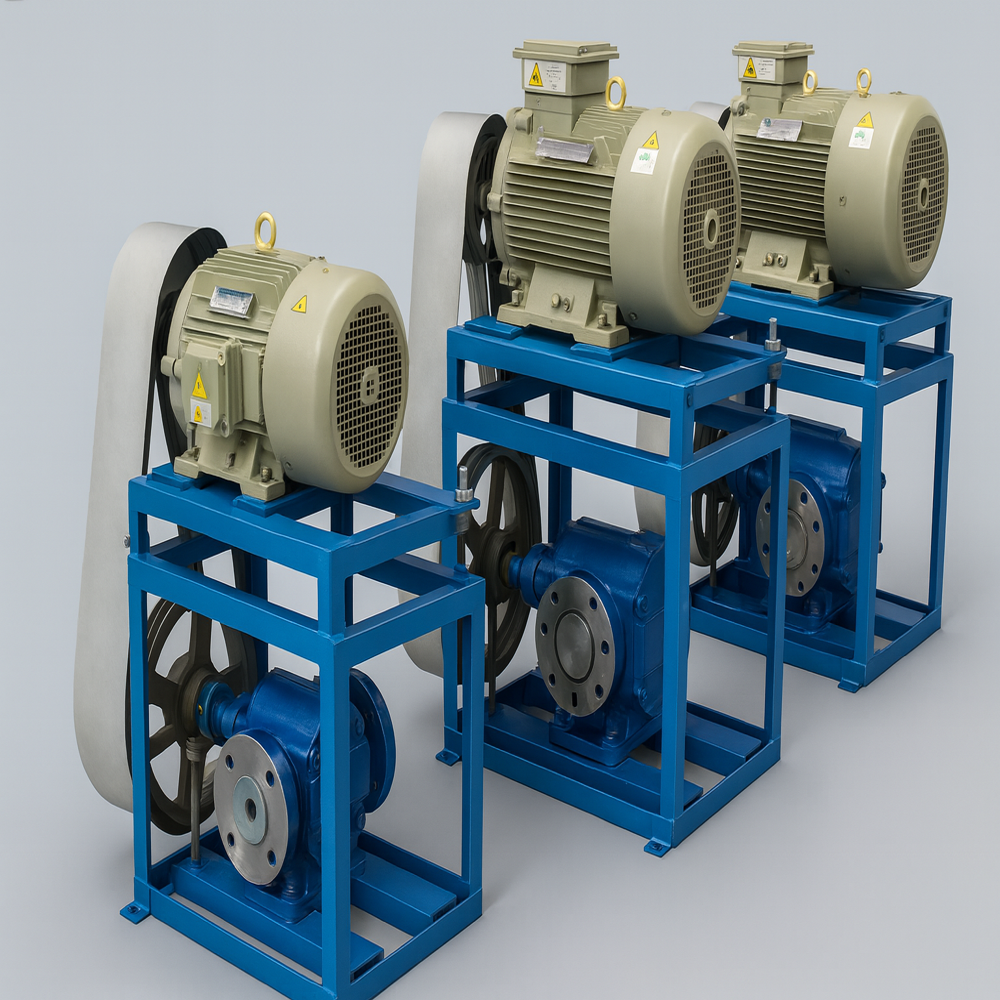

They are available in centrifugal, rotary lobe, and progressive cavity configurations, depending on your flow rate, head, and viscosity requirements.

These pumps are engineered with high torque capability, anti-clogging internals, and optional heating jackets to ensure smooth operation and prevent crystallization or blockages during transfer.

Each pump is custom-built to suit your process requirements, ensuring reliability, high performance, and minimal maintenance downtime.

Key Features & Benefits

- Handles High Viscosity Liquids: Designed to efficiently pump molasses and other dense, sticky materials.

- Corrosion-Resistant Construction: Available in SS304, SS316, Cast Iron, or special alloys for long life.

- Smooth & Steady Flow: Ensures consistent transfer without pulsation or clogging.

- Heating Jacket Option: Maintains proper fluidity by preventing crystallization in low-temperature environments.

- Energy-Efficient Performance: Optimized impeller or rotor designs reduce power consumption.

- Low Noise & Vibration: Precision-balanced components ensure quiet, vibration-free operation.

- Leak-Proof Operation: Equipped with high-quality mechanical seals and shaft protection sleeves.

- Easy Maintenance: Modular construction allows quick disassembly and servicing.

- Heavy-Duty Bearings: For long operational life even under continuous-duty cycles.

- Customizable Design: Available in multiple capacities, materials, and drive options.

Applications

Ajay Engineering Molasses Transfer Pumps are ideal for a wide range of industrial uses, including:

- Sugar Mills: Transferring molasses between clarifiers, tanks, and evaporators.

- Distilleries: Feeding molasses to fermentation tanks or distillation columns.

- Ethanol Production Plants: Continuous molasses feed for blending and processing.

- Food & Beverage Industry: Syrup, glucose, treacle, and viscous fluid transfer.

- Chemical & Fertilizer Plants: Handling thick organic or inorganic liquids.

- Tankers & Storage Systems: Loading and unloading molasses or syrup tanks.

- Biofuel Units: Viscous feedstock transfer for bioethanol or biodiesel production.

Technical Specifications

Why Choose Ajay Engineering

Ajay Engineering Delivering Reliability, Efficiency & Innovation for the Viscous Fluid Industry.

Frequently Asked Questions (FAQs)

Q1. What is a Molasses Transfer Pump?

It is a specialized industrial pump used to transfer thick molasses and other high-viscosity liquids in sugar and distillery plants.

Q2. What makes Ajay Engineering a pioneer in this field?

Ajay Engineering has decades of specialized experience, in-house design, and proven performance across hundreds of sugar and distillery installations.

Q3. Can the pump handle very thick molasses?

Yes our pumps are designed for viscosities up to 1,000,000 cP and can be equipped with heating jackets to maintain fluidity.

Q4. What materials are used in construction?

Options include Cast Iron, SS304, SS316, and special alloys depending on process fluid properties.

Q5. Can you provide turnkey solutions?

Yes we supply complete pumping systems including motor, base frame, piping, and instrumentation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+