Molasses Feeding Pump

Product Details:

- Voltage 415 Volt (v)

- Flow Rate 500 LPH to 50000 LPH

- Inlet/Outlet 1 to 6 Inch

- Head Size 5 Meters to 50 Meters

- Working Temperature 30-80 Celsius (oC)

- Theory Rotary Pump

- Seals Type Gland Packing

- Click to View more

Molasses Feeding Pump Price And Quantity

- 10 Unit

- 30000.0 INR/Unit

Molasses Feeding Pump Product Specifications

- Gland Packing

- 5 Meters to 50 Meters

- Rotary Pump

- 30-80 Celsius (oC)

- 500 LPH to 50000 LPH

- 1 to 6 Inch

- 415 Volt (v)

Molasses Feeding Pump Trade Information

- Vadodara

- 10 Unit Per Day

- 7 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packl

- Asia

- North India, East India, Arunachal Pradesh, All India, South India, Central India, West India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Telangana, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Nagaland, Rajasthan, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Manipur, Andhra Pradesh, Bihar, Maharashtra, Sikkim, Tamil Nadu, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

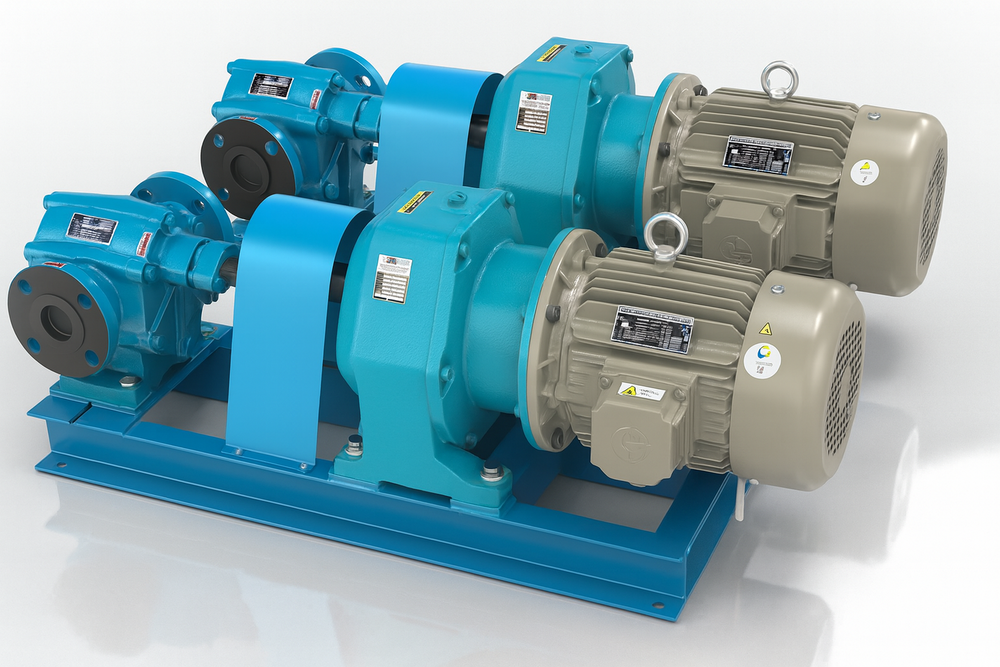

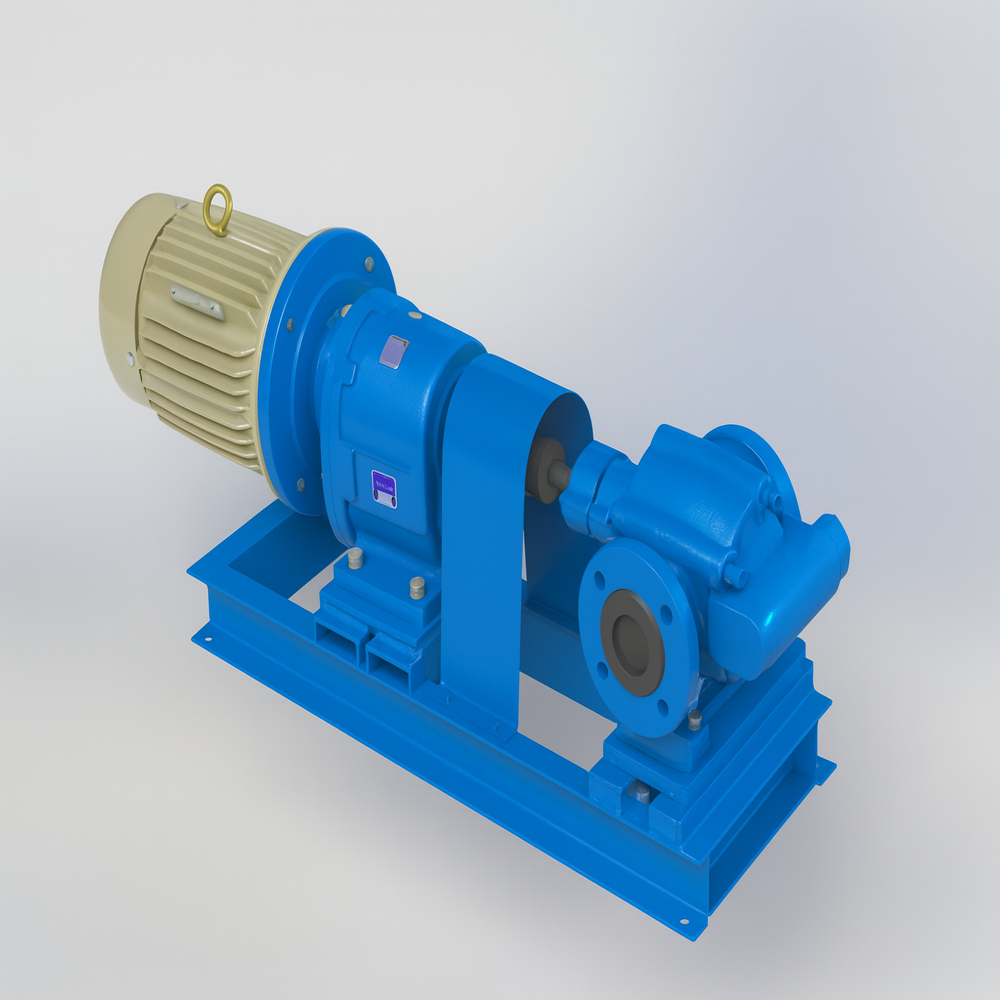

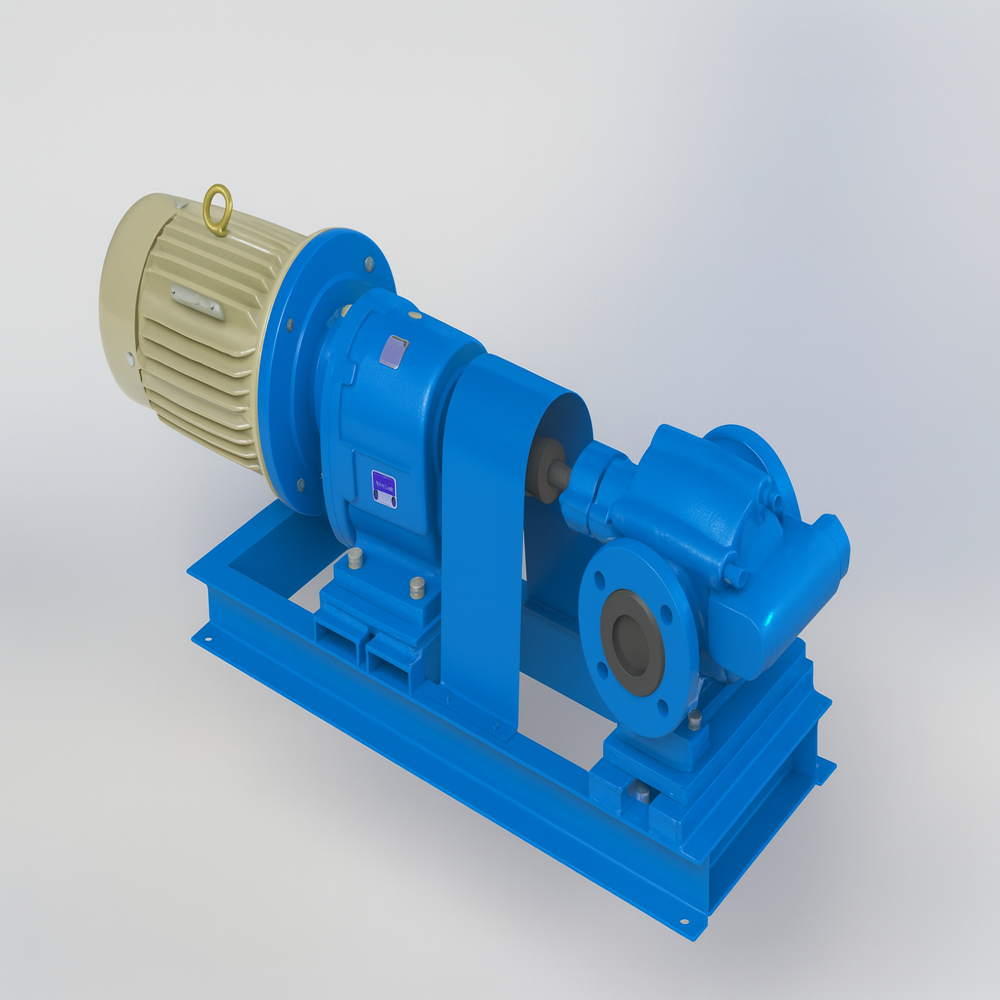

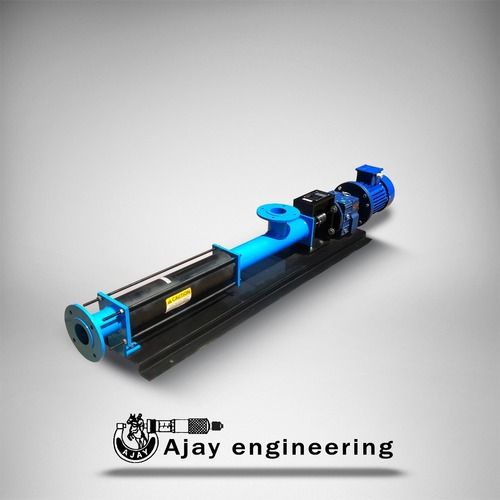

The Ajay Engineering Molasses Feeding Pump is specially developed to handle thick, sticky, and high-viscosity fluids like molasses.

These pumps maintain a steady and uniform feed flow to fermenters and process tanks, preventing blockages and ensuring consistent production rates.

The pump can be customized with heating jackets, stainless steel wetted parts, and different drive configurations as per process requirements. Its ideal for applications where viscosity, temperature, and hygiene are crucial.

Key Features & Benefits

- High Viscosity Handling: Specially designed impeller and rotor geometry to efficiently transfer heavy molasses without clogging.

- Uniform Flow Rate: Ensures continuous feeding for fermenters and process equipment.

- Corrosion-Resistant Materials: Available in Cast Iron, SS304, SS316, and other special alloys for long-lasting durability.

- Heating Jacket Option: Prevents crystallization and maintains fluidity of molasses during colder conditions.

- Low Maintenance Design: Easy to service, with quick access to seals and bearings.

- Energy Efficient: Optimized hydraulic design reduces power consumption and improves efficiency.

- Custom Built Solutions: Available in multiple models, discharge capacities, and drive options (electric motor, geared drive, belt drive).

- Leak-Free Operation: Equipped with high-quality mechanical seals or gland packing for zero leakage.

- Silent & Vibration-Free Running: Precision balancing ensures smooth and quiet operation.

- Heavy-Duty Construction: Built to handle continuous operation in sugar and distillery environments.

- Sugar Mills - For feeding molasses from storage tanks to process units

- Distilleries & Breweries- For continuous feeding of molasses into fermenters

- Ethanol Plants - For metered transfer of viscous molasses to blending units

- Food Processing - Handling syrups, glucose, treacle, and other viscous food products

- Chemical & Fertilizer Plants - Pumping thick, sticky liquids and slurries

- Storage & Transfer Systems - For tanker unloading and tank circulation applications

Technical Specifications

Why Choose Ajay Engineering

- Decades of Expertise: With years of innovation, Ajay Engineering is recognized as a pioneer in molasses pump manufacturing across India.

- Custom-Engineered Solutions: Every pump is designed as per customer process parameters viscosity, temperature, and head.

- In-House Manufacturing: State-of-the-art production ensures consistent quality and performance.

- Comprehensive After-Sales Support: Installation guidance, spare parts, and maintenance support available.

- Turnkey Pumping Packages: Complete skid-mounted systems with piping, valves, and controls can be provided.

- Quality Assurance: Each pump undergoes hydrostatic, performance, and leak testing before dispatch.

- molasses feeding pump manufacturer

- molasses feeding pump supplier in India

- Ajay Engineering molasses feeding pump

- molasses transfer pump for distillery

- molasses pump for sugar mill

- high viscosity molasses pump

- stainless steel molasses pump

- corrosion resistant molasses pump

- sugar industry molasses feeding pump

- heavy-duty molasses pump manufacturer

Frequently Asked Questions (FAQs)

Q1. What is a Molasses Feeding Pump?

A molasses feeding pump is designed to transfer thick, sticky molasses from storage tanks to process units or fermenters in sugar and distillery plants.

Q2. Why choose Ajay Engineering Molasses Feeding Pump?

Because Ajay Engineering is a pioneer manufacturer offering proven designs, high durability, and energy-efficient operation for viscous liquid handling.

Q3. Can the pump handle heated or cold molasses?

Yes, optional heating jackets or temperature control features are available to maintain proper flow in cold conditions.

Q4. Are customized pumps available?

Yes, pumps are tailor-made based on capacity, viscosity, discharge head, and process layout.

Q5. What type of maintenance is required?

Minimal maintenance due to robust construction, replaceable seals, and easy serviceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+